Why OEM Hard Steel Concrete Nails are Essential for Your Construction Projects

Why OEM Hard Steel Concrete Nails are Essential for Your Construction Projects

Understanding OEM Hard Steel Concrete Nails

OEM Hard Steel Concrete Nails are specifically designed for fastening materials in construction projects, particularly where concrete is involved. These nails are manufactured to high standards, ensuring they can withstand significant stress and environmental conditions. The "

Why OEM Hard Steel Concrete Nails are Essential for Your Construction Projects

Understanding OEM Hard Steel Concrete Nails

OEM Hard Steel Concrete Nails are specifically designed for fastening materials in construction projects, particularly where concrete is involved. These nails are manufactured to high standards, ensuring they can withstand significant stress and environmental conditions. The "OEM" designation signifies that these nails can be tailored to meet specific project requirements, providing flexibility and customized solutions for contractors and builders alike.

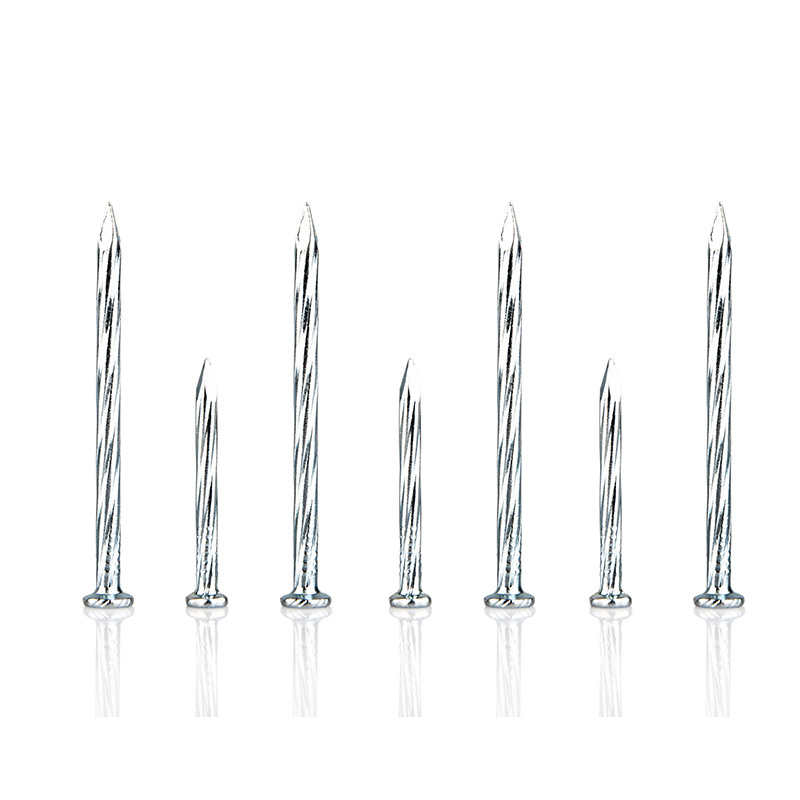

The Composition of Hard Steel Concrete Nails

Hard steel concrete nails are made from high-carbon steel, which is known for its strength and durability. This steel undergoes specific heat treatment processes that enhance its hardness and wear resistance. The result is a nail that can penetrate tough materials like concrete and masonry without bending or breaking.

Key Characteristics of Hard Steel Concrete Nails

- **High Tensile Strength:** These nails are engineered to endure high levels of tensile stress, making them ideal for heavy-duty applications.

- **Corrosion Resistance:** Many OEM hard steel concrete nails come with protective coatings that resist rust and corrosion, ensuring longevity even in harsh conditions.

- **Precision Engineering:** The manufacturing process ensures uniformity in size and shape, facilitating accurate installation.

The Importance of Using OEM Hard Steel Concrete Nails

Choosing the right fasteners is crucial in construction, as they are fundamental to the structural integrity of any project. OEM hard steel concrete nails play a vital role in ensuring stability and safety.

Durability and Reliability

One of the primary reasons to opt for OEM hard steel concrete nails is their exceptional durability. These nails are designed to bear heavy loads, making them suitable for both residential and commercial construction. Their ability to hold fixtures securely over time decreases the risk of structural failure, which could lead to costly repairs and unsafe environments.

Applications in Construction

- **Concrete Fixtures:** Whether installing concrete blocks, beams, or other heavy elements, these nails provide the grip needed for secure installation.

- **Framing and Formwork:** In framing structures, OEM hard steel concrete nails ensure that wooden forms remain stable during the pouring of concrete.

- **Roofing and Siding:** For exterior applications, these nails can effectively secure materials against wind and weather.

Benefits of Using OEM Hard Steel Concrete Nails

Understanding the advantages of these nails can help construction professionals make informed choices.

Cost-Effectiveness

While OEM hard steel concrete nails may have a higher upfront cost compared to standard nails, their durability translates into long-term savings. Fewer replacements and reduced maintenance costs make them a more economical choice over time.

Enhanced Safety

Using high-quality nails reduces the likelihood of accidents on-site. The strong hold provided by OEM hard steel concrete nails minimizes the risk of materials loosening, which can lead to injuries.

Versatility in Use

OEM hard steel concrete nails can be used in various applications beyond just concrete work. Their strength allows them to fasten wood, metal, and other materials, making them a versatile option for diverse construction tasks.

Choosing the Right OEM Hard Steel Concrete Nails

Selecting the appropriate nails for your project is crucial for success. Here are some key factors to consider.

Nail Size and Length

The size and length of the nails you choose depend on the materials you are fastening. For heavy-duty applications, longer nails are necessary to ensure a secure hold.

Understanding Load Requirements

Assessing the load requirements of your project is essential. Consider the weight that the nails need to support, and choose accordingly. This ensures the fasteners will not fail under pressure.

Coating and Treatment Options

Different coating options are available, including galvanized and epoxy-coated nails, which provide additional protection against corrosion. Choosing the right coating depends on environmental factors, such as moisture levels and exposure to chemicals.

Installation Tips for OEM Hard Steel Concrete Nails

Proper installation is key to maximizing the effectiveness of your nails.

Using the Right Tools

Investing in quality tools, such as a hammer or nail gun designed for concrete nails, can make the installation process smoother and more efficient. Ensure your tools are compatible with the size and type of nails you are using.

Correct Hammering Technique

When hammering the nails, it's essential to apply consistent pressure and angle. This technique helps prevent bending and ensures that the nails penetrate the material effectively.

Pre-drilling When Necessary

In some cases, pre-drilling the holes can help reduce the chances of cracking the concrete, especially in hard materials. This technique allows for easier nail insertion and minimizes stress on the surrounding area.

FAQs about OEM Hard Steel Concrete Nails

1. What are OEM Hard Steel Concrete Nails made of?

OEM hard steel concrete nails are typically made from high-carbon steel, which is treated to enhance its hardness and overall strength.

2. How do I choose the right size of concrete nails for my project?

Consider the materials you are fastening and the load requirements. Longer nails are generally preferred for heavier applications to ensure a secure hold.

3. Can I use OEM Hard Steel Concrete Nails for wood projects?

Yes, these nails are versatile and can be used for various applications, including fastening wood materials, thanks to their strength and durability.

4. What makes OEM Hard Steel Concrete Nails more cost-effective in the long run?

Their durability reduces the need for frequent replacements and maintenance, leading to overall cost savings over time.

5. Are there special tools required for installing these nails?

Using a quality hammer or nail gun designed specifically for concrete nails is advisable to ensure proper installation and reduce the risk of bending or breaking.

Conclusion

Incorporating OEM hard steel concrete nails into your construction projects is not merely a choice; it is a fundamental investment in quality and safety. With their exceptional durability, versatility, and reliability, these nails ensure that your projects are not only successful but also long-lasting. By understanding the critical aspects of selecting and installing these nails, you can make informed decisions that enhance the integrity of your structures. Consider the advantages of using OEM hard steel concrete nails as you plan your next construction project, and elevate your building endeavors to new heights.

TAG:

Prev

Recommended

Why OEM Hard Steel Concrete Nails are Essential for Your Construction Projects

Why OEM Hard Steel Concrete Nails are Essential for Your Construction Projects

Understanding OEM Hard Steel Concrete Nails

OEM Hard Steel Concrete Nails are specifically designed for fastening materials in construction projects, particularly where concrete is involved. These nails are manufactured to high standards, ensuring they can withstand significant stress and environmental conditions. The "